MANUFACTURING

Engineered for Precision, Built to Perform

At Vasus, manufacturing isn’t just a process—it’s an integrated ecosystem built for precision, performance, and reliability. We manage the complete production journey in-house, from raw material formulation to final assembly of advanced brake systems.

This end-to-end approach gives us total control over quality, consistency, and customization. Each stage—from material science, automated machining, to component testing—is powered by skilled experts, smart machines, and global best practices.

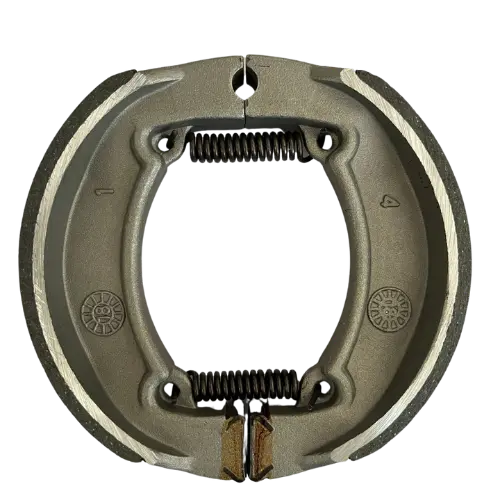

Brake Shoe Manufacturing Process

1. Raw Material Prep & Casting

Aluminum ingots are selected, stored, and then melted in a furnace. The molten aluminum is used for high-pressure die casting to form the basic brake shoe body.

2. Machining & Cleaning

The cast shoe is machined to the correct shape (radius milling) and then cleaned via shot blasting to prepare the surface for the lining material.

3. Lining Preparation (Friction Material)

The raw ingredients for the friction material (lining) are weighed, mixed, and preformed into shape. This preform is then heat-molded under high pressure.

4. Assembly & Finishing

The shoe is coated with adhesive, and the molded friction lining is applied via an automatic adhesive spray line. Final machining (slitting, grinding the side and OD) is done to ensure the correct dimensions and finish.

5. Final Product

The completed brake shoe is ready for use.

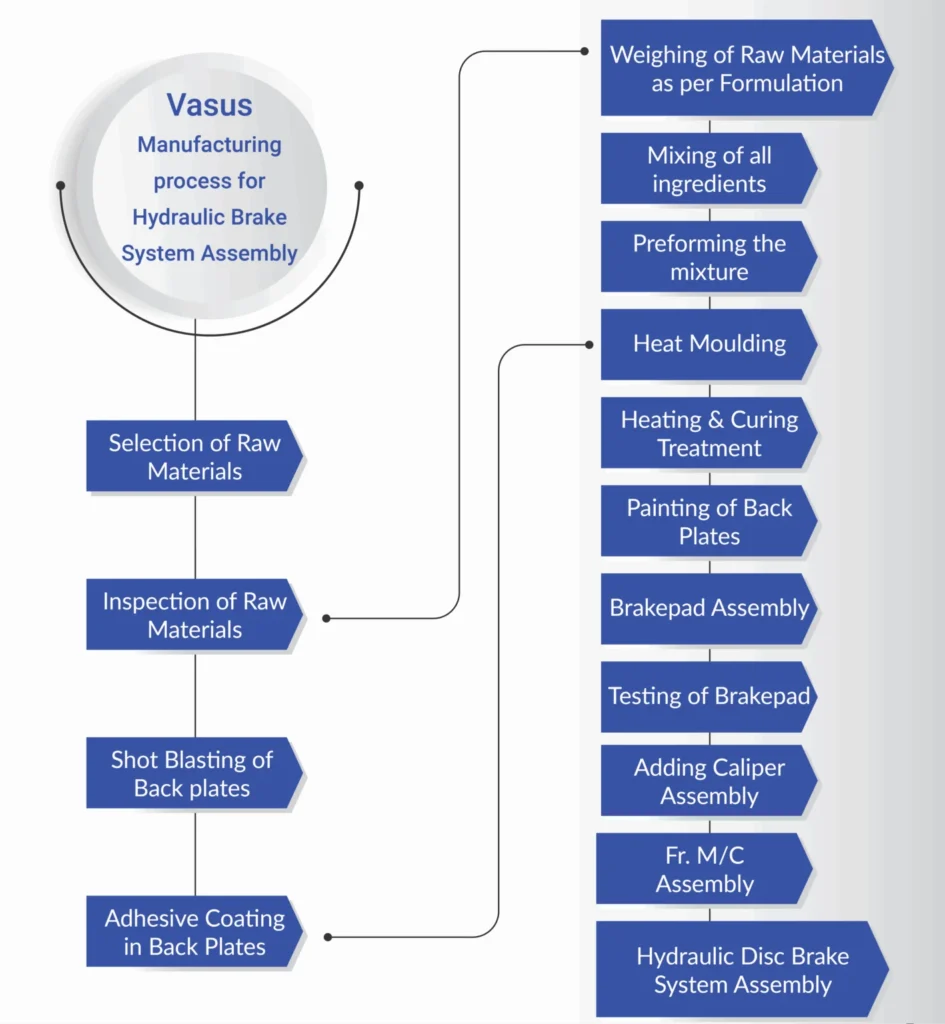

Brake Pad Manufacturing Process

1. Back Plate Preparation

Steel back plates are sourced (or made), inspected, degreased, and then shot blasted to create a rough surface for better adhesion. An adhesive coat is applied.

2. Friction Material Production

Raw friction material ingredients are weighed, mixed (in a Plough Mixer), and preformed into a slug.

3. Moulding & Curing

The friction material slug is bonded to the back plate using heat and high pressure (heat moulding) and then cured in an oven.

4. Finishing & Assembly

The completed pad assembly is painted/powder-coated for protection. Final grinding and slitting are performed to meet dimensional requirements.

5. Final Product

The finished brake pad assembly is complete.

Smart Processes, Smarter Machines

We combine intelligent systems and automation to ensure every brake

system is reliable, consistent, and performance-ready.

🤖 CNC Automation

Precision machining for consistent output

📡 Digital Controls

Real-time monitoring + AI-powered adjustments

🔍 Inspections

Strict quality checks at every production phase

📊 Data-Driven

Metrics-driven improvements & insights

⭐ Why Vasus Stands Out

- Tailored Engineering Solutions We cater to niche demands and Industry-specific challenges with customized friction materials and designs

- ISO-Certified Processes Globally recognized standards ensure repeataability, safety

- Global Reach, Local Strength Trusted by OEMs and distributors across. Europe, Asia, and the Middle East

- Scalable Production Capacity Our automated systems allow us to scale up production quickly without compromising on quality or delivery timelines.

- Scalable Production Capacity Our automated systems allow us to scale up production quickly without compromising on quality or delivery timelines.